Classification of cable insulation materials and their characteristics in detail

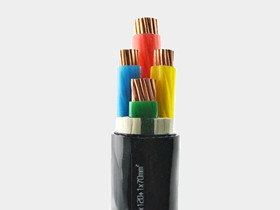

PVC: Polyvinyl chloride is a polymer formed by the free polymerization of vinyl chloride monomers under specific conditions. With the characteristics of stability, acid resistance, alkali resistance, corrosion resistance and aging resistance, it is widely used in building materials, daily necessities, pipelines, wires and cables, sealing materials, etc. It is divided into soft and hard: soft is mainly used to make packaging materials, agricultural films, etc., and is widely used in the manufacture of wire and cable insulation layers, such as: ordinary PVC insulated power cables; while hard is generally used For the production of pipes and plates, etc. The biggest feature of polyvinyl chloride material is flame retardancy, so it is widely used in the field of fire prevention. It is one of the most common insulating materials for flame-retardant and fire-resistant wires and cables.

PE: Polyethylene is a thermoplastic resin obtained by polymerization of ethylene. It is non-toxic and harmless, has excellent low temperature resistance, and can resist most acids and alkalis, and has excellent electrical insulation properties. At the same time, because polyethylene has the characteristics of non-polarity, it has the characteristics of low loss and high electrical conductivity, so it is generally used as an insulating material for high-voltage wires and cables.

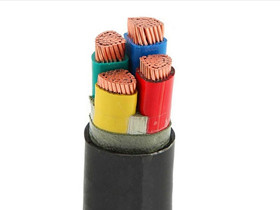

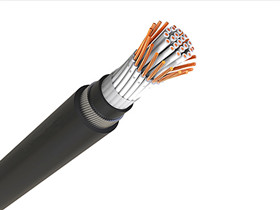

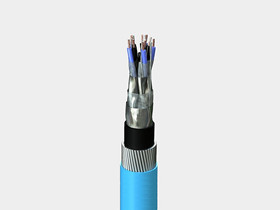

XLPE: cross-linked polyethylene, which is an advanced form of polyethylene material after transformation. After improvement, its physical and chemical properties have been greatly improved compared with PE materials, and at the same time, its heat resistance level has been significantly improved. Therefore, wires and cables made of cross-linked polyethylene insulation have the incomparable advantages of wires and cables made of polyethylene insulation: light weight, good heat resistance, corrosion resistance, relatively large insulation resistance, etc.

Compared with thermoplastic polyethylene, XLPE insulation has the following advantages:

1. Improve heat deformation resistance, improve mechanical properties at high temperature, improve environmental stress cracking resistance and heat aging resistance.

2. Enhanced chemical resistance and solvent resistance, reduced cold flow, basically maintained the original electrical properties, long-term working temperature can reach 125 ° C and 150 ° C, cross-linked polyethylene insulated wire and cable, also improved Short-circuit withstand capacity, its short-term withstand temperature can reach 250 ° C, and the current-carrying capacity of XLPE is much larger for wires and cables of the same thickness.

3. XLPE insulated wire and cable has excellent mechanical, waterproof and radiation resistance properties, so it has a wide range of applications. Such as: electrical internal connection wires, motor leads, lighting leads, automotive low-voltage signal control wires, locomotive wires, subway wires and cables, mining environmental protection cables, marine cables, nuclear power laying cables, TV high-voltage wires, X-RAY firing high-voltage wires, and power Transmission wire and cable industries.

The difference between PVC, PE and XLPE cable insulation materials

PVC: low working temperature, short thermal aging life, small transmission capacity, low overload capacity, great smoke and acid gas hazards in case of fire. General-purpose product in the wire and cable industry, with good physical and mechanical properties, good processing performance, low cost and selling price. But containing halogen, the amount of sheath is the largest.

PE: Excellent electrical performance, with all the advantages of PVC above. Commonly used for wire or cable insulation, data line insulation material, low dielectric constant, suitable for data lines, communication lines, various computer peripheral wire core wire insulation.

XLPE: The electrical properties are almost as good as PE, while the long-term working temperature is relatively higher than that of PE, the mechanical properties are better than PE, and the aging resistance is better. A new type of environmental protection product with good high temperature resistance and environmental resistance, thermosetting plastic. It is often used in electronic wires and places with high environmental requirements.

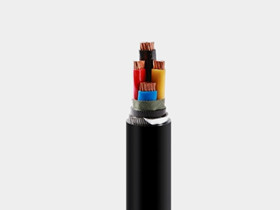

The difference between XLPO and XLPE

XLPO (cross-linked polyolefin): EVA, low-smoke halogen-free, radiation cross-linked or vulcanized rubber cross-linked olefin polymer. Obtained by individual polymerization or copolymerization of α-olefins such as ethylene, propylene, 1-butene, 1-pentene, 1-hexene, 1-octene, 4-methyl-1-pentene and some cycloolefins A general term for a class of thermoplastic resins.

XLPE (cross-linked polyethylene): XLPE, cross-linked polyethylene, silane cross-linked or chemically cross-linked, is a thermoplastic resin made by polymerization of ethylene. In industry, it also includes copolymers of ethylene and a small amount of α-olefins.