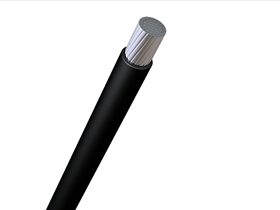

The followings are the possible reasons which could result surface blackening of AAAC Conductor

First, the production process of aluminum alloy strands: At present, most of China's wire and cable plants had same equipment and production process. Basically, aluminum Alloy ingots for remelting containing 99.70% of aluminum are purchased from the market, and then according to process requirements and aluminum ingots. The chemical element, the aluminum ingot is processed by itself, and the aluminum Alloy rod for electrician is produced by the continuous casting and ligation process, and then the aluminum rod is drawn into a round aluminum alloy wire with a small diameter by a sliding wire drawing machine or a non-sliding wire drawing machine, and finally The aluminum alloy wire are twisted together into a aluminum alloy strand by a frame or other standing machine. The production of large-section aluminum alloy wires is usually carried out by continuous casting and ligation-sliding high-speed aluminum wire drawing machine-630 frame stranding machine to ensure the manufacturing quality of large-section wires.

Second, through the analysis of the example of blackening of aluminum aaloy wires, several main factors affecting the blackening of the surface of aluminum alloy wires are obtained:

Factor 1: (the effect of high temperature and humidity) Although the manufacturing processes of the various manufacturers are the same, the performance of the products in different regions is not the same. In general, aluminum alloy wires have no surface blackening in dry and low temperature areas but may appear in high temperature and humid areas become Black.

Factor 2: (the impact of rain and sun exposure) After the wire has been transported for a long time, and the rainfall is too high, the wire is exposed to rain and then exposed to high temperature, and the surface may appear black.

Factor 3: (the influence of gas in the atmosphere) Under outdoor exposure conditions, aluminum has high corrosion resistance. Generally, the gas in industrial atmosphere has no effect on the corrosion performance of aluminum conductor. The oxygen in the atmosphere has the greatest influence on the surface of aluminum, followed by carbon and carbonization in the atmosphere. The particles of the material, the third is the sulfur compound, oxygen has been confirmed to have a corrosive effect on the surface of aluminum, especially in acidic solutions, high concentration of dissolved oxygen will accelerate the corrosion of aluminum, carbon and carbide particles precipitated in aluminum on the surface, the surface of carbon (C) and aluminum wire forms a corrosive galvanic cell in the presence of water vapor. The aluminum is accelerated as an anode. The sulfur compound has no special effect on aluminum, and the acidic solution contains S02 and S03. It has a certain corrosive effect on aluminum. As long as the contaminated water is in contact with aluminum for a long time, or if it is in contact with wet and porous materials, it will cause blackening of the surface, and in wet conditions such as aluminum wire and moisture-proof material (such as wood). Where the cloth, insulating paper, etc. are in contact with each other, it will be easier to blacken, so the storage location and storage method of the steel-cored aluminum stranded wire are the most important.

Factor 4: (The effect of moisture in the atmosphere) Water vapor is an excellent electrolyte. It combines with oxygen, pollutants in the atmosphere, and pollution residues on the surface of aluminum conductors. As a result, the air in the air on the surface of the aluminum alloy wire contains more and more water vapor, and the water vapor in the air increases. When it is supersaturated, there is a drop of water. The surface of the aluminum alloy wire is blackened and strongly affected by the temperature and humidity of the air. Under various conditions in the atmosphere, there is no adverse effect on aluminum alloy . Under the combined action of moisture and high temperature, the chemical components and pollutants in the atmosphere will cause corrosion of the aluminum conductor, which is a necessary condition for the blackening of the surface of the aluminum alloy conductor.