What is overhead service drop cable ?

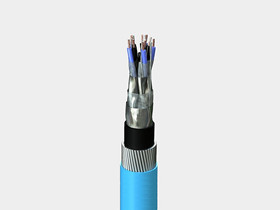

Overhead service drop cables are the cables that supply outdoor overhead power lines. They are a new power transmission method between overhead conductors and underground cables, which began research and development in the early 1960s. They were first widely used in countries such as Europe and America. In the early 1980s, China had many backbone manufacturers of overhead aerial bundle cable production, with different conclusions on their own characteristics and scope of use.Overhead service drop cables are composed of an insulation layer and a protective layer, similar to the production process of cross-linked cables. Although they are more susceptible to external interference and are not aesthetically pleasing, they are widely used in places where it is difficult to lay underground cables due to their high power supply reliability, stability, and convenient maintenance.

How we select overhead service drop cable ?

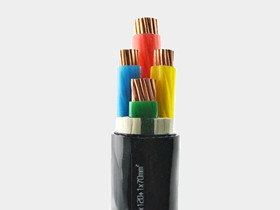

The three types of aluminum service drop cables are duplex service drop cable, triplex service drop cable, and quadruplex service drop cabble. They differ according to the number of conductors and common applications. Let's briefly focus on the role of each of these.Duplex service drop cables with two conductors are used in single-phase power lines for 120-volt applications. They are frequently used in lighting systems outdoors, including street lighting. Moreover, they are often used in the construction business for temporary service. Fun fact- American duplex overhead cable sizes are named after dog breeds, including setter, shepherd, and chow.

Triplex service drop cables with three conductors are used to carry power from the utility lines to customers, in particular, to the weather head. Again, American triplex service drop cables have an interesting story to their name. They are named after the species of sea animals, such as snails, clams, and crabs. Cable names include Paludina, Valuta, and Minex.

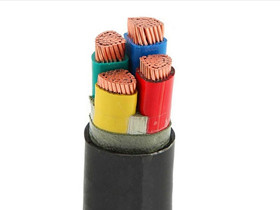

Quadruplex service drop cables with four conductors are designed to supply three-phase power lines. They connect pole-mounted electrical transformers, mostly located in the rural areas, with the service heads of the end-user. Quadruplex cables that pass the requirements of NEC are named after horse breeds, such as Gelding and Appaloosa.

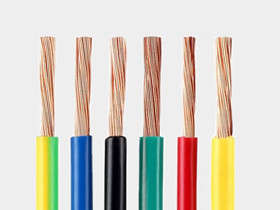

The characteristics of hard aluminum wire are light structural weight, moderate tensile force, easy bending, convenient installation, low cost, and can be easily installed on existing towers for use. It is generally used in renovation or new construction projects.

The characteristic of hard drawn copper wire is its heavy structure, but its tensile force is relatively large and its resistance to external forces is also strong. Even if the tower is broken, the cable can still be energized. In addition, the aluminum alloy wire structure is lightweight and has strong tensile strength, mainly used in tower systems with a span of 100m.

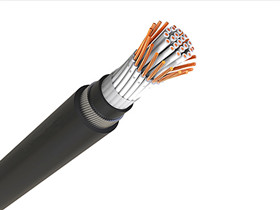

The 35kV voltage system generally adopts a steel core or aluminum alloy core support structure, and a square insulator is used to separate the support wire (bare wire) from three insulated phase lines. The support wire can be used as a lightning conductor. Its biggest advantage is its small sag, and the arc weight is only about 2.4% of the span.

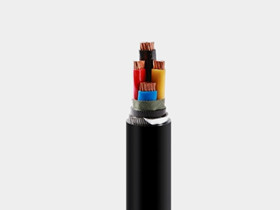

The medium span system adopts a self-supporting three core stranded structure. The disadvantages of this type of cable are that the manufacturing length of a three core cable is shorter than that of a single core cable, there are more joints, and there is an outer semi conductive shielding layer. The terminal head or stress cone structure should be installed at the end of the cable like a regular cable.

Looking at the above, it is easy to find that the conductors of overhead service drop cables are all made of aluminum wire.

What is the reason?

1. Aluminum has strong conductivity and relatively light weight, making it suitable for use in high, middle, and high schools.

2. Aluminum has the ability to resist corrosion and has good insulation.

3. Aluminum has a high cost-effectiveness ratio.

4. Indoor copper and aluminum wire connections are prone to line failures, but cables in high altitude do not, so only aluminum wire is needed.