SIP-4 Cable Description

SIP-4 wire is a self-supporting insulated conductor equipped with high quality aluminum conductive conductors. Light-stabilized cross-linked polyethylene is used as the main insulating layer.

The cross-section of the conductive conductors of this wire can be from 10 to 240 square mm, their number can be in the range from 1 to 4. It is allowed to use auxiliary conductive conductors of a smaller section together with the main ones, the so-called “four plus” wires, for example SIP-4 4×25 + 1×16; 4×35 + 1×25; 4×50 + 1×25; 4×50 + 1×35; 4×70 + 1×25; 4×70 + 1×35; 4×70 + 1×50; 4×95 + 1×50; 4×95 + 1×70; 4×120 + 1×70; 4×120 + 1×95; 4×150 + 1×95; 4×150 + 1×120; 4×185 + 1×120; 4×185 + 1×150; 4×240 + 1×150; 4×240 + 1×185.

More demanded nomenclatures in the SIP-4 wire, with a section of 2×16, 2×25, 4×16, 4×25, 4×35, 4×50, 4×70, 4×95, 4×120, the price of an SIP wire depends on two parameters – the section and the number of cores, since this is the main costly part in the production of conductor products.

SIP Cable Application

Power supply of end consumers (facility, living quarters), as well as lighting of various areas can be carried out using self-supporting insulated wires. One of the types of SIP, which is used for these purposes, is the SIP-4 wire in question. A feature of this type is the absence of a carrier zero core. This type of cable is used to equip branches from overhead power lines to transformer units. They can be used for the construction of lighting power grids or for laying on the walls of construction sites. The main technical properties of insulated electric wires provide the ability to operate in alternating current networks at 1000 Volts and 50 Hz.

SIP-4 Cable Construction

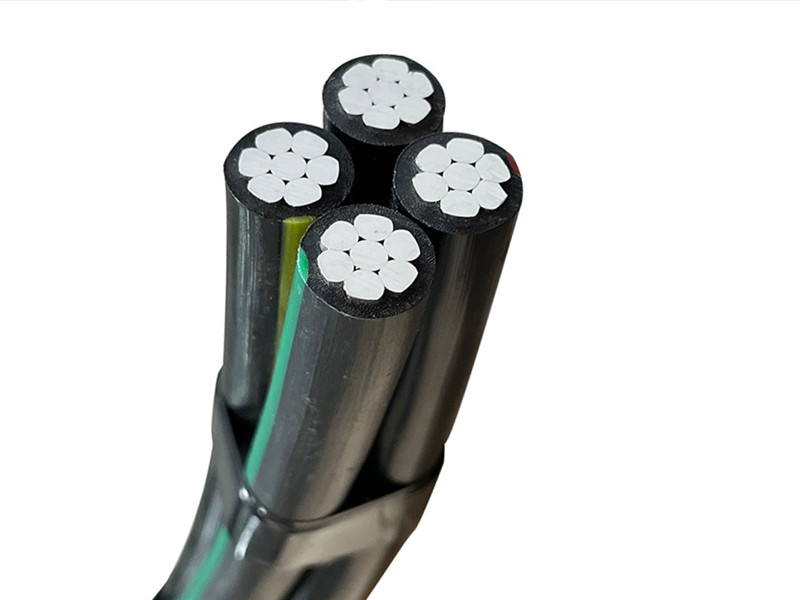

SIP-4 is made of compacted aluminum wire with a twist pitch of up to 45 cm. The wire, as a rule, has 2-3-4 conductive stranded conductors of the same nominal cross-section, and also, in some cases (as mentioned above), an additional smaller conductor is added section.

The wire is mainly produced with a cross section of 16-120 mm2. In this case, if the nominal cross-section does not exceed 25 mm2, a right-sided twisting is used, for large sizes – a left-sided one.

All cores of the wire are insulated with thermoplastic light-stabilized black cross-linked polyethylene, resistant to ultraviolet radiation throughout the entire service life.

This insulation provides the cable with resistance to all types of atmospheric precipitation, as well as to significant and sharp changes in ambient temperature.

Deciphering SIP-4:

What does the abbreviation SIP mean? This abbreviation stands for –

S – self-supporting

I – isolated

P – wire

4 – type of design

|

Specifications

|

|

Permissible heating temperature of current-carrying conductors during overload mode (up to 8 hours per day)

|

130°С

|

|

Permissible heating temperature of current-carrying conductors in case of short circuit with short circuit current flow up to 5 seconds

|

250°С

|

|

Operating temperature

|

от -60 °С до +50 °С

|

|

Minimum wire laying temperature

|

-20 °С

|

|

Long-term permissible core heating temperature

|

+90 °С

|

|

Minimum bending radius when laying

|

10 wire diameters

|

|

Minimum service life

|

25 years

|

| Number and nominal cross-section of conductors, mm2 |

Outer wire diameter, mm |

Estimated weight of 1 km of wire / 1kg |

Nominal insulation thickness |

| SIP-4 2х16 |

17.2 |

142.6 |

1.3 |

| SIP-4 2х25 |

19.8 |

205.5 |

1.3 |

| SIP-4 3х16 |

15.7 |

206 |

1.3 |

| SIP-4 3х25 |

18.1 |

292 |

1.3 |

| SIP-4 4х16 |

20.08 |

285.3 |

1.3 |

| SIP-4 4х25 |

23.9 |

410.9 |

1.3 |

| SIP-4 4х35 |

27.1 |

544.7 |

1.3 |

| SIP-4 4х50 |

30.9 |

730.8 |

1.5 |

| SIP-4 4х70 |

35.6 |

1014.1 |

1.7 |

| SIP-4 4х95 |

41.5 |

1358.5 |

1.7 |

| SIP-4 4х120 |

45.2 |

1683.2 |

1.7 |